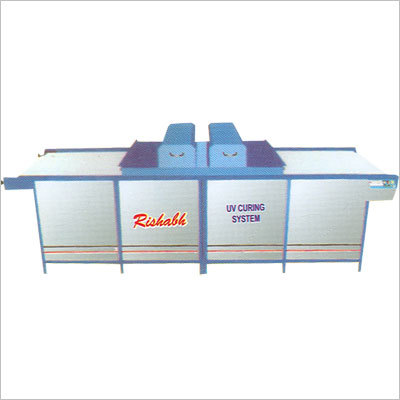

Fully Automatic UV coating and Curing System

Price 1200000 INR/ Sheet

Fully Automatic UV coating and Curing System Specification

- Type

- Fully Automatic UV Coating and Curing System

- Material

- Stainless Steel and Industrial Grade Components

- Capacity

- Customizable, typically up to 5000 sheets/hour

- Printing Speed

- Up to 50 m/min, depending on substrate

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Plate Type

- Flatbed/Sheetfed

- Print Direction

- Bidirectional

- Ink Type

- UV Curable Coating

- Color Management

- Integrated Color Calibration

- Control System

- PLC Controlled with Touchscreen Interface

- Working Temperature

- 5C - 40C

- Power

- 8-15 kW (depending on model)

- Size

- Standard and Custom Sizes Available

- Width

- Available in 500 mm, 800 mm, and 1200 mm working widths

- Weight (kg)

- Approx. 1200-2500 kg (depending on configuration)

- Dimension (L*W*H)

- Approx. 5800 x 1700 x 1650 mm

- Voltage Requirement

- 380V / 50Hz, 3 Phase

- Suitable Substrates

- Paperboard, Cardboard, Plastic Sheet, Metal Foil

- Lamp Cooling

- Forced Air Cooling with Temperature Protection

- Safety Features

- Emergency Stop, Overload Protection, UV Light Shield

- Conveyor System

- Anti-Static Conveyor Belt

- Delivery System

- Auto Stacker with Jogger

- Coating Uniformity

- ±2 Microns

- Coating Viscosity Range

- 50-120 mPas

- Curing Type

- High-Intensity UV Lamp, Quartz-Cooled

- Noise Level

- <75 dB

- Feeder Type

- Automatic Feeder with Anti-Double Sheet Detection

Fully Automatic UV coating and Curing System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Fully Automatic UV coating and Curing System

| Capacity | 5000 sheets per hour |

| Power | 200-500 W |

| Automatic Grade | Automatic |

| Material | Iron |

| Weight | 150 - 175 kg |

We are one of the foremost firms ofiFully Automatic UV Curing System.iBesides, we present this product at nominal rates to our customers.

Advanced Coating Accuracy

Achieve consistent results with coating thickness uniformity of 2 microns, supporting a broad viscosity range of 50-120 mPas. Integrated color calibration systems and computerized controls ensure optimal visual output and process reliability across paper, plastic, and metal substrates.

Robust Automation for Maximum Productivity

The system features an automatic feeder with anti-double sheet detection and auto-stacker delivery with jogger, maximizing sheet handling efficiency and minimizing operator intervention. With capacities up to 5000 sheets per hour and wide format options, it supports high-volume operations.

Reliable UV Curing and Safety Assurance

A high-intensity UV lamp, forced air and quartz cooling, and comprehensive safety elements including emergency stop, overload protection, and UV light shields ensure safe, effective, and fast curing. The anti-static conveyor allows smooth material flow with a noise level below 75 dB for quieter working environments.

FAQ's of Fully Automatic UV coating and Curing System:

Q: How does the automatic anti-double sheet detection ensure smooth feeding in the UV coating system?

A: The automatic feeder uses advanced sensors to identify and prevent double-sheet feeding, which helps maintain coating accuracy, reduces waste, and avoids jams or misfeeds during high-speed operations.Q: What types of substrates can be processed with this fully automatic UV coating and curing system?

A: This system is suitable for a wide variety of substrates, such as paperboard, cardboard, plastic sheets, and metal foil, offering exceptional coating quality and versatility for diverse industrial applications.Q: When should the UV coating system be used in the production process?

A: The UV coating system is typically used after the primary printing process to apply protective and decorative finishes, delivering durable, glossy, and scratch-resistant surfaces to printed materials.Q: Where can this UV coating and curing system be installed?

A: This equipment is designed for installation in industrial production areas such as print finishing units, packaging facilities, and large-scale print shops, thanks to its customizable size and configuration options.Q: What process steps ensure uniformity and quality in UV coating application?

A: The system uses a flatbed/sheetfed plate mechanism, anti-static conveyor, and integrated color calibration to deliver even coatings across substrates, consistently maintaining 2 microns uniformity throughout the process.Q: How does forced air cooling and quartz tube protection benefit UV lamp performance?

A: Forced air and quartz-cooling work together to dissipate heat quickly, extending lamp life, ensuring optimal curing temperature, and protecting the surrounding components from excessive heat buildup.Q: What are the main benefits of using a fully automatic, PLC-controlled UV coating system?

A: Key benefits include enhanced productivity, reduced manual errors, precise coating control, improved safety through multiple protection features, and adaptability to varied production scales, making it ideal for large commercial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in UV Curing System Category

UV Curing Machines

Price 200000 INR / Sheet

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1800 mm x 650 mm x 1200 mm

Color Management : Other, Standardized

Computerized : Yes

Plate Type : Other, Flatbed

UV Curing Equipment

Price 200000 INR / Sheet

Minimum Order Quantity : 1 Sheet

Dimension (L*W*H) : 2000mm 900mm 1200mm

Color Management : Other, Standard CMYK

Computerized : Yes

Plate Type : Other, Flatbed

Combo Dryer (UV, IR, HOT AIR)

Price 250000 INR / Sheet

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 3100 mm x 940 mm x 1120 mm

Color Management : Other, Manual adjustment

Computerized : No

Plate Type : Other, Flat plate compatible

GST : 06AHAPS9194C1Z6

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS